Pharmaceutical Product development

- Solubility Enhancement (BCS Class II & IV) “Enhancing bioavailability of poorly soluble API (BCS Class II & IV) which will lead to better therapeutics efficacy."

- Modified Release

- Taste Masking

- Dispersions (Emulsion/Suspension/ Gels/Creams)

- Services for High Potent API (HPAPI) and non-potent API

Herbal & Nutraceutical Product development

- Solubility Enhancement

- Taste Masking

- Dispersion (Emulsion/ Suspension / Gels / Creams)

- Encapsulation of essential oils and Flavors

- Improving dispersibility of Herbals extracts

- Herbal Product Stability enhancement

- Reducing bioburden of herbals

High Potent API (Cytotoxic, Hormones & Steroids) Product development

More than 40% of anticancer drugs, are poorly water-soluble, hence these drug’s results in poor bioavailability (BA) and high intra- and inter-individual pharmacokinetic variability. Solid dispersion by HME improves solubility and being a contained system there is low dust formation and hence safe for handling of high potent drugs.

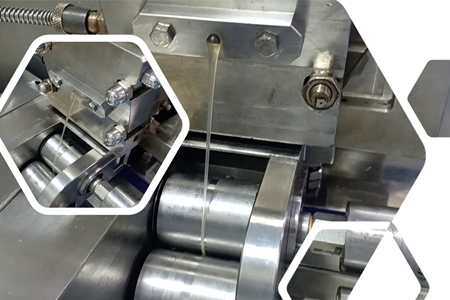

Continuous manufacturing using Twin Screw Processor

We provide services for Product development by Twin screw processor for

- Melt Granulation,

- Wet Granulation

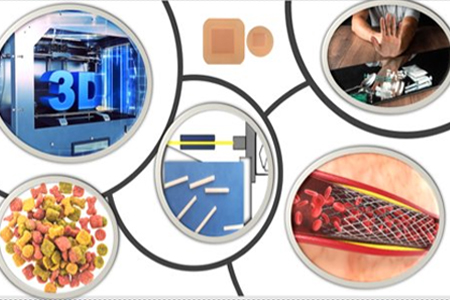

Upcoming Specialized Formulation Capability

- Implants (parenteral & Dental)

- Abuse deterrent technologies

- Transdermal patches

- Fast Dissolving oral films

- Drug Eluting Stents

- Chews for Veterinary application

- 3D-Printing

Product Development (composition & Process) Service and Activities:

| Type of Development | Development Activities | Description of Activities | No. of Trials | Total material Qty. required* | |

|---|---|---|---|---|---|

| End-to-End | Partial | Feasibility or POC trials | Assess technical feasibility (Screening of polymer/s, excipients and process condition) |

5-10 | 0.1 – 1 kg |

| Prototype or trials | Develop prototypes formulations by HME, meeting the broad specification | 10-30 | 2 – 5 kg | ||

| Long run Trials | Understanding the stability of the process run. (Run time 1-3 hrs) | 1-3 | 1-6 kg | ||

| Pilot bio batch and stability | Manufacturing of the Pilot bio batch at identified manufacturing site | 1 – 3 | 1 – 5 kg | ||

| Optimization Trial | DoE run to define design space for composition and process | 6-20 | 1 – 2 kg | ||

| Scaleup | Scale up and Engineering batch |

Scale up on same scale of HME (long run) or higher scale HME at commercial scale |

5-10 | Depends on scale of the HME machine | |

| Commercial manufacturing | Exhibit batch manufacturing at identified manufacturing site | 3 | Depends on scale of the HME machine | ||

* The drug loading would be 10 – 70 based on the product requirement

Process Development Service and Activities:

| Sr. no. | Development Activities | Description of Activities | No. of Trials | Total material Qty. required* |

|---|---|---|---|---|

| 1 | Feasibility or POC trials | Feasibility trial on HME using the composition provided by client | 5-10 | 0.1 – 1 kg |

| 2 | Only Process development | Developing process on HME using the composition provided by client | 10 -20 | 2-3 kg |

| 3 | Troubleshooting | Trouble shooting for the process by providing HME process solution | NA | NA |

By :

By :