"SWALAVA is a reliable Contract Research Organization (CRO) and a partners for your product development."

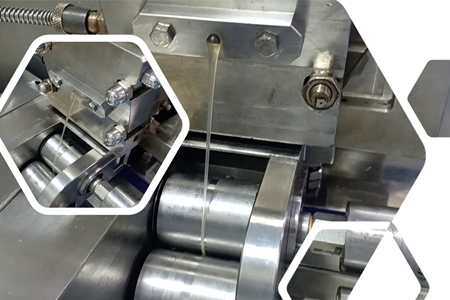

We offers profound know-how and expertise based on hands-on experience with Hot Melt Extrusion (HME) and related technologies from initial idea to scale-up and technology transfer at the identified commercial site. Swalava team has more than a decade of experience in Hot Melt Extrusion/ Twin-screw Processing technology and has been involved in scale-up ranging from 5 - 200 kg/hr

We have the capability to develop pharmaceutical (Potent and Non-potent) / Herbal /Nutraceutical products using Hot Melt Extrusion (HME) technology. One of our unique expertizes is for handling thermolabile drugs through HME.

OUR SERVICES

Pharmaceutical Product development

- Solubility Enhancement (BCS Class II & IV) “Enhancing bioavailability of poorly soluble API (BCS Class II & IV) which will lead to better therapeutics efficacy."

- Modified Release

- Taste Masking

- Dispersions (Emulsion/Suspension/ Gels/Creams)

- Services for High Potent API (HPAPI) and non-potent API

Herbal & Nutraceutical Product development

- Solubility Enhancement

- Taste Masking

- Dispersion (Emulsion/ Suspension / Gels / Creams)

- Encapsulation of essential oils and Flavors

- Improving dispersibility of Herbals extracts

- Herbal Product Stability enhancement

- Reducing bioburden of herbals

High Potent API (Cytotoxic, Hormones & Steroids) Product development

More than 40% of anticancer drugs, are poorly water-soluble, hence these drug’s results in poor bioavailability (BA) and high intra- and inter-individual pharmacokinetic variability. Solid dispersion by HME improves solubility and being a contained system there is low dust formation and hence safe for handling of high potent drugs.

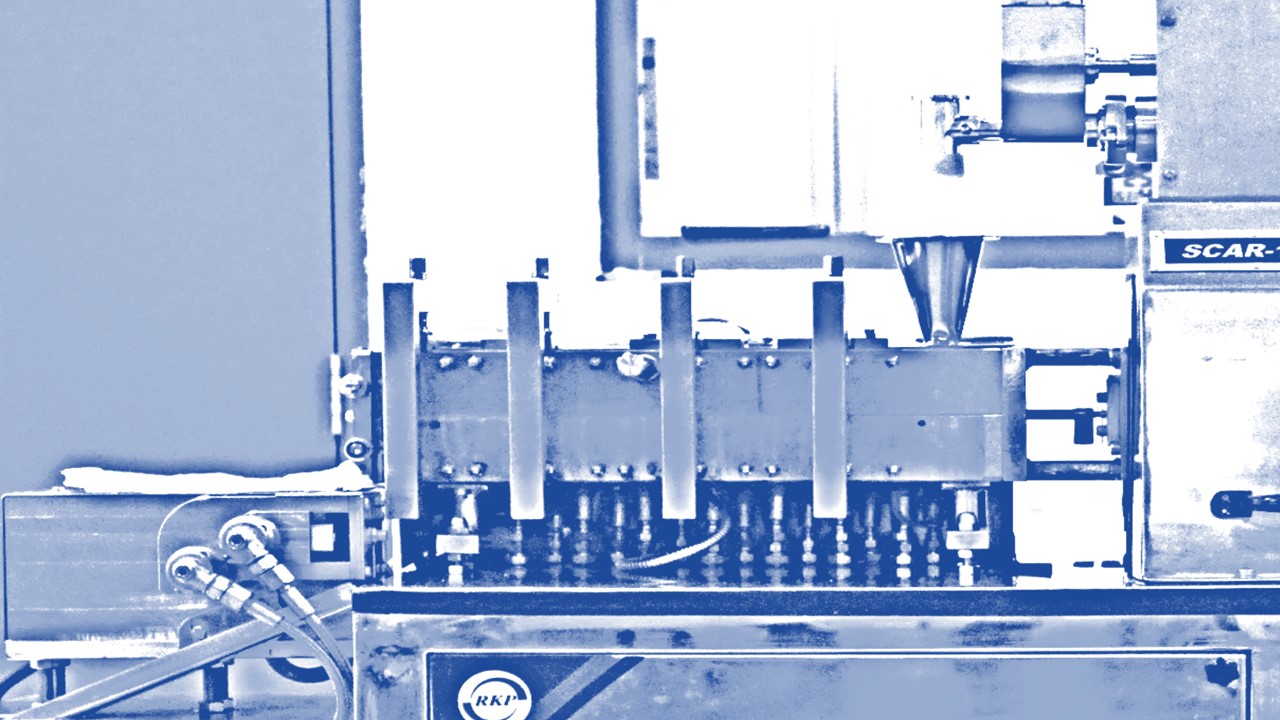

Continuous manufacturing using Twin Screw Processor

We provide services for Product development by Twin screw processor for

- Melt Granulation,

- Wet Granulation

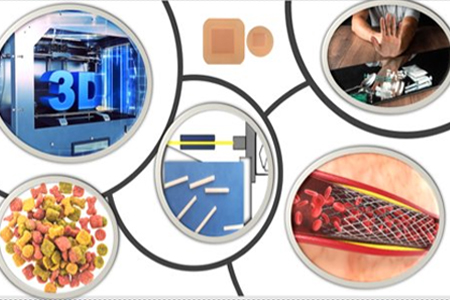

Upcoming Specialized Formulation Capability

- Implants (parenteral & Dental)

- Abuse deterrent technologies

- Transdermal patches

- Fast Dissolving oral films

- Drug Eluting Stents

- Chews for Veterinary application

- 3D-Printing

SPECIAL FEATURES

We offer some awesome features that will help you

Processing of very thermolabile API

SWALAVA team has experience and expertise in handling thermolabile API for solubility enhancement using HME technology. The API which can degrade/decomposes more than 90% using the HME process, Swalava team has capability to even process these Thermolabile API meeting the regulatory requirement of the product.

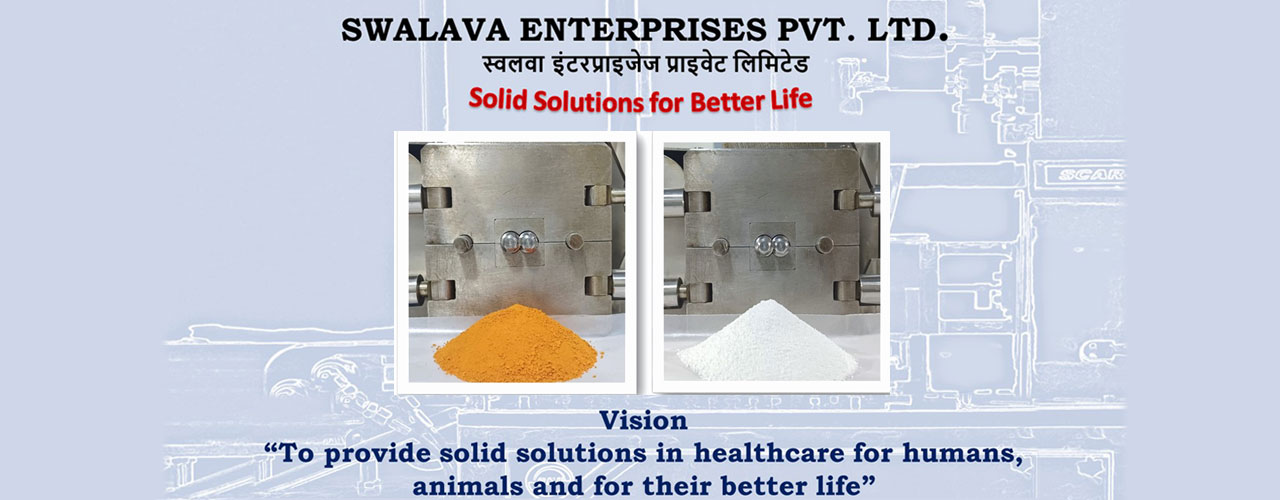

Processing of material in HME using pressurised gas

SWALAVA team has experience in processing material using pressurised gas Carbon-di-oxide or Nitrogen inside the HME. This unique process help to reduce the processing temperature and thereby prevent drug degradation. Processing under pressurised gas also help to improve the milling efficacy of the difficult to mill material and achieve very low particle size.

Converting Crystalline API to Amorphous using HME

Converting an Crystalline API to Amorphous form resulting into patent circumventing pathways as well as possibility of claiming own IP.

Lifecycle management

Converting Spray drying process to an efficient and simple HME process.

By :

By :